Home → CONTROL SYSTEM FOR AB3 AND AB8 GAS COMPRESSOR STATIONS

PLANT DESCRIPTION

Each station has:

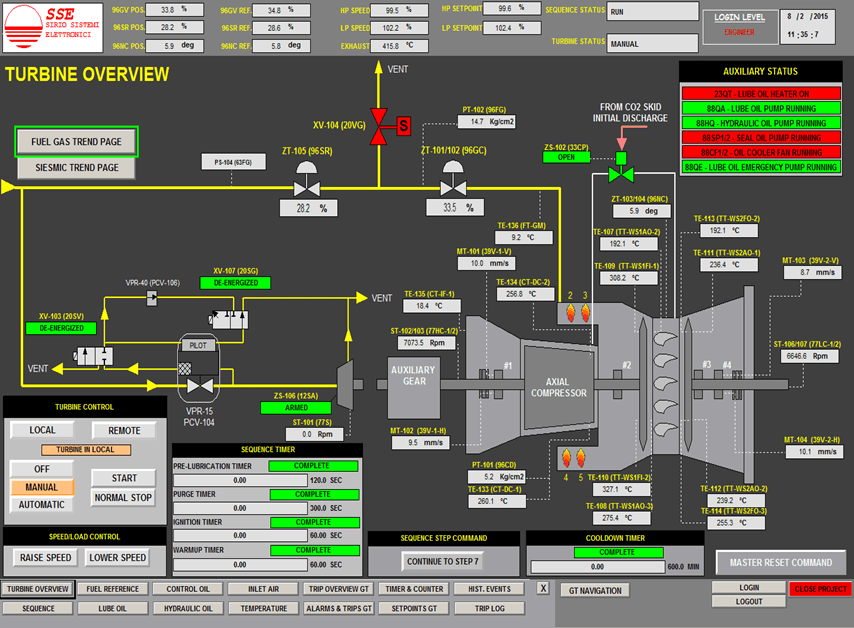

Each gas turbine compressor has a dedicated control system configured to:

The existing No. 3 compressor control panels, located in station AB3, will remain as they are. The control panels for gas turbine n°3 at station AB3 will be replaced by the new control system n°3, based on Rockwell Automation's PLC and supervisory computers.

The existing compressor control panel and gas turbine control panel located at station AB8 will be replaced by the new compressor control system n°1 and gas turbine control system n°1, both based on Rockwell Automation PLC computers and supervisory computers.

The actual functionality, control values and performance of the gas turbine compressor must be guaranteed and maintained as they are.

SSE carried out the preliminary research and collected all the basic engineering information to replace the existing control system cabinets. SSE developed detailed engineering, construction, SW configuration and testing for new control system cabinets. The existing control panels in the control room were removed and replaced with new CCS and UCP cabinets. The complete upgrade of the AB8 compressor station control system was implemented, including the anti-surge algorithms and the centrifugal compressor performance controller. SSE technicians operated during the installation, pre-commissioning and commissioning activities, up to the start-up of the complete station, while the SSE professor trained the Customer's operation and maintenance teams. The CCS and UCP cabinets feature a Rockwell Automation ControlLogix PLC with full "redundant" HOT STAND-BY CPU architecture and simplex I/O. All installation renewal activity was carried out without interrupting the station's normal production. To meet this requirement, the shutdown of one gas turbine at a time was designed and managed during the complete installation and start-up phase. The new control system in the control room is equipped with operator workstation n°2 and engineering workstation n°1 from station AB8, operator workstation n°3 and engineering workstation n°1 from station AB3 in multi-unit configuration based on FactoryTalk supervision, RSLogix configuration software.

SSE carried out the preliminary research and collected all the basic engineering information to replace the existing control system cabinets. SSE developed detailed engineering, construction, SW configuration and testing for new control system cabinets. The existing control panels in the control room were removed and replaced with new CCS and UCP cabinets. The complete upgrade of the AB8 compressor station control system was implemented, including the anti-surge algorithms and the centrifugal compressor performance controller. SSE technicians operated during the installation, pre-commissioning and commissioning activities, up to the start-up of the complete station, while the SSE professor trained the Customer's operation and maintenance teams. The CCS and UCP cabinets feature a Rockwell Automation ControlLogix PLC with full "redundant" HOT STAND-BY CPU architecture and simplex I/O. All installation renewal activity was carried out without interrupting the station's normal production. To meet this requirement, the shutdown of one gas turbine at a time was designed and managed during the complete installation and start-up phase. The new control system in the control room is equipped with operator workstation n°2 and engineering workstation n°1 from station AB8, operator workstation n°3 and engineering workstation n°1 from station AB3 in multi-unit configuration based on FactoryTalk supervision, RSLogix configuration software.

HIGHLIGHTS

Project type:

Mechanical and electrical upgrade of the existing control into an integrated control system for gas turbine compressor trains.

The new control system must guarantee very safe, robust, reliable, durable and economical means of operating gas turbine trains

Scope of supply:

Design, engineering, construction SW configuration and testing of the new unit control panel (UCP) for gas turbine compressor trains.

Installation, commissioning and start-up of the UCPs in the control rooms.

BENEFIT

- Increased plant "availability" thanks to reduced unplanned stoppages, reduced downtime for troubleshooting,

- Fully integrated plant control

- Repair and remove spare parts from the shelf.

- Optimized plant performance resulting from rapid and precise monitoring and control of functional parameters.