Home → ANTI-SURGE CONTROL AND MOTOR-COMPRESSOR PERFORMANCE

The Cacimbas Gas Treatment Unit treats gases and condensates coming mainly from the Golfinho field, and natural gas from the Peroá Field (PPER-1), in the municipality of Linhares, ES. The Sul-Norte Capixaba Gas Pipeline, which will expand the company's natural gas flow capacity between the southern and northern regions of the state of Espírito Santo.

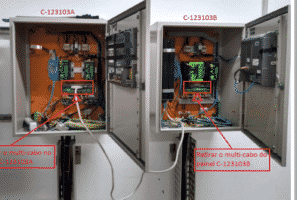

SSE supplied three control panels for the unit (one per pair of motor-compressors) and SSE technicians operated them during the commissioning activities, also providing technical assistance during all the critical start-up phases of the new project cycle.

SSE Brasil's solution consisted of modernizing the process of anti-surge and performance, via a control panel per pair of each of the plant's 6 Sundyne compressors.

The items developed by the engineering team were:

- Applicable reference documentation:

- Control and protection anti-surge (AS) SSE:

- SSE performance control:

- Implementation and philosophy of compressor control:

This process has a start-up specific, because the electric motors and compressors are designed to operate under the working conditions of the process: the propane gas in the suction of the compressors must be close to vacuum pressure and the temperature must be 10°C maximum. In fact, when the plant starts up for the first time, the propane gas conditions must be very different from the design conditions: the propane temperature must be close to the ambient temperature and the propane pressure depends on the amount of propane used to pressurize the cycle. This means that when the compressor starts, an overload trip of the electric motor can occur.

To avoid this, some dedicated functions are developed in the control system:

In each panel, the Rockwell CompactLogix PLC is installed and configured with the plant's customized algorithms. Each panel consists of a FactoryTalk View supervision system installed on an industrial computer with an operating system Windows IoT Enterprise on the front panel.

To do this, the control system manages all the main auxiliary and machine valves through automatic or manual sequences. It also manages the permissive to start and the compressor disarm in emergency cases.

Therefore, valve management in automatic mode allows the system to pressurize the compressor before it starts, without operator intervention.

| PRODUCTION | 3 control panel units (1 for each pair of Sundyne compressors) |

| CONTROLLER | Rockwell CompactLogix PLC |

| SUPERVISORY | FactoryTalk |

SUMMARY

SSE operates in the field of industrial control solutions and carries out the design, software development, production and commissioning of Control and Supervisory Systems for the Oil & Gas and Power Generation Industries. SSE's main task is to supply and repair control and supervision systems for rotating machinery and associated auxiliary systems.

The controller normally used in these applications is the PLC.

Following is the list of PLCs generally used in our applications:

In any case, in gas turbine control applications, dedicated PLCs are commonly used:

At least one HMI (Human Machine Interface) is usually developed for the control panel.

SSE uses SCADA (Supervisory Control and Data Acquisition) supervisory software to develop the HMI. Following the main supervisory software used:

HIGHLIGHTS

BENEFITS