Home → Services and Equipment → Gas liquefaction solutions

Gas liquefaction solutions

SMALL SCALE -

SCALABLE CAPACITIES

SSE has developed a solution for a small-scale liquefaction plant with a nominal LNG production capacity of 15tpd, scalable from 10tpd to 30tpd.

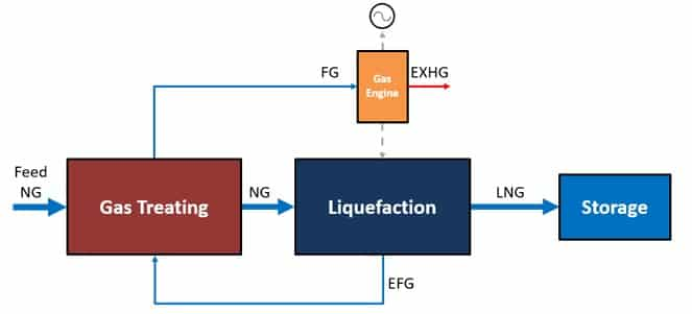

The plant configuration was simulated and designed for SSLNG applications that receive feed gas from the pipeline. Liquefaction of bio-methane is also possible after upgrading the biogas.

SSE's solution results in an installation based on minimal equipment, with an efficient solution, intelligent and rational simplification of auxiliary systems, reduced plant presence and minimal CAPEX (CAPital EXpenditure) and OPEX (OPerational EXpenditure) with remote operation and supervision capacity.

- Plant capacity of 10 ~ 30 tons / day

- Pipeline feed gas or upgraded biogas

- Economic solution and CAPEX and OPEX

- Waste heat recovery with the possibility of producing hot water to be used by other customers' processes and auxiliaries

- Low-voltage power generation for all electrical equipment

- No MV electrical subsystems required

- Reliable equipment available on the market based on the manufacturer's proven standard design.

- Simple and reliable operation by unqualified personnel

PROCESS SELECTION AND SIMULATIONS

SSE has the in-house capability to simulate and validate feed gas treatment and liquefaction processes based on various refrigerant cycles (i.e. N2, CH4, MR) using specific software for powerful process simulation to design and optimize processing facilities.

- Methane refrigerant cycle

- Nitrogen refrigerant cycle